Flattening optical element’s surface manually

A spinning turntable is wet with water and dressed with a powdered abrasive that has been dissolved in water by gently dragging from the center to the outer edge of the turntable. The abrasive spreads over the turntable surface in a whirlpool pattern. An optical element is then pressed against the table to neatly flatten the face perpendicular to the optical axis. Known as “flattening,” this process is done manually by hand rather than by an automated machine. The above photograph captures a moment during this process at our Iiyama factory. How wet should the turntable be? How much abrasive should be used? How strongly should an optical element be pressed against the turntable and for how long? There is no instruction manual to answer these questions.

To protect the parts of the optical element that are not pressed against the turntable, they are coated in a black protective agent. Similar to sharpening a knife blade on a grindstone, the edge faces of an optical element are made perfectly smooth and flat. The evenness of the grain is judged with the eye. Cosina adds this flattening process to some of its high-end interchangeable lenses to ensure that there are absolutely no problems with optical performance. The sensitivity and skill required for this process are passed down from veteran workers to new employees so that we can continue to make our high precision lenses.

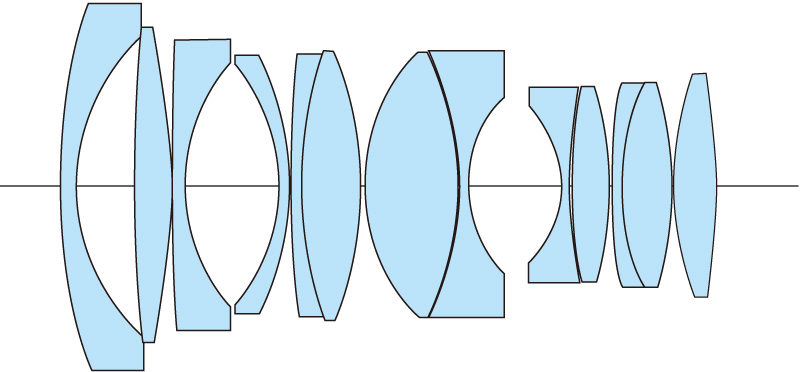

Can you tell by looking at this optical diagram which element was “flattened?” The answer is the very first concave element. Particularly with wide-angle SLR lenses of retro-focusing type, the first element has a wide diameter. So, if you look through the lens from the front, you can see the surface perpendicular to the optical axis, therefore attention must be given to esthetics. Of course, pictures cannot be taking while peering down a lens from the front, but we think it is important nonetheless to seriously meet the demand of users who want complete esthetic beauty since esthetics are considered a part of performance. That is why we add this flattening process without fretting over the associated hassles and time.