Aluminum, the prize in recycling

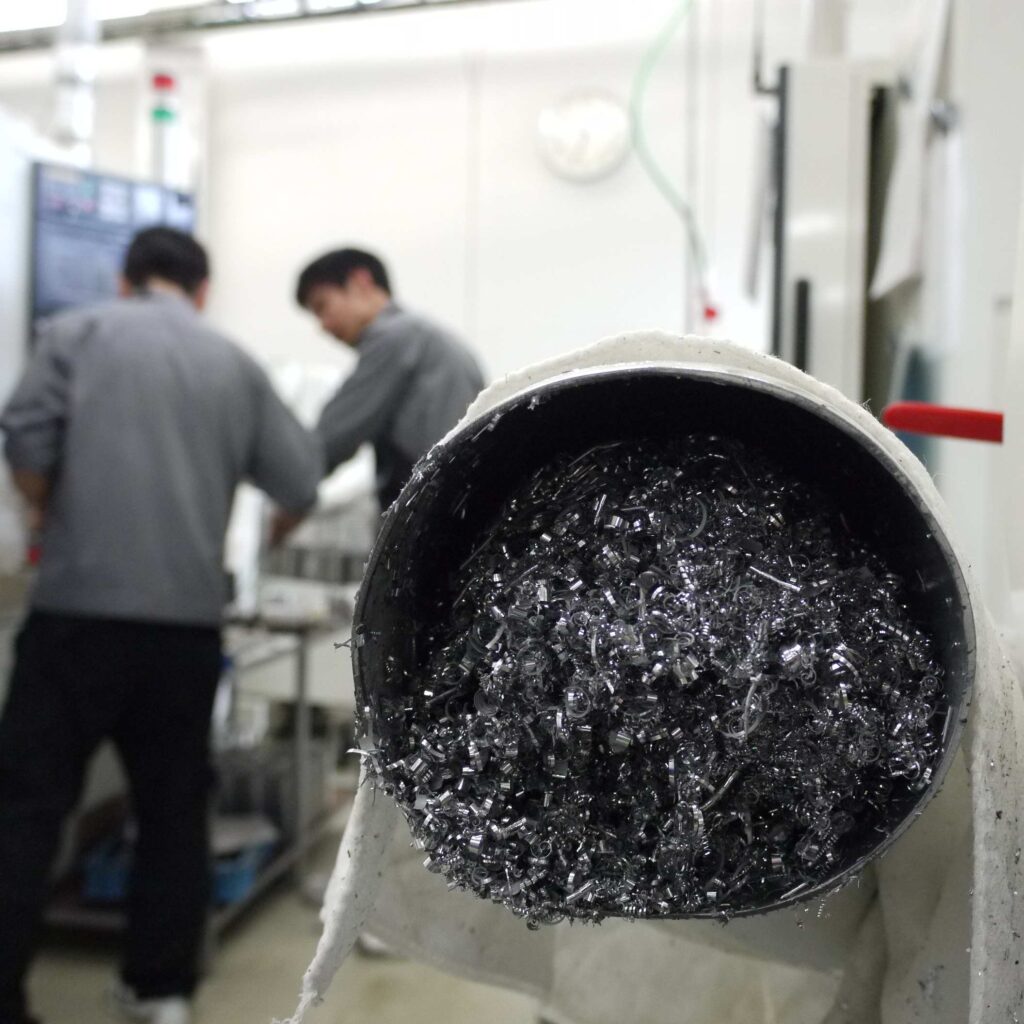

We mill metals into products of excellent durability with stringent levels of dimensional accuracy. The containers in our yard are piled high with shiny metal chips and cuttings left over from manufacturing processes. Upon closer inspection, the bigger pieces look like the ridgeline on a flower-shaped shade used for a wide-angle lens. And, that’s exactly where they came from. The cuttings shown in the above photo are what is left over after cutting out the shade from a cylindrical piece of material stock. It is, so to speak, a round partial piece created when trying to make a hole in a doughnut. These chips and cuttings are not processed as waste but passed on to a specialist who recycles them into viable industrial materials.

Metal machining processes generate thin strips of metal of no definable shape. These strips are collected with larger cuttings of same material and recycled. Of the various metal materials we use, aluminum is said to be the prize in recycling. Making virgin aluminum from bauxite requires a large amount of electricity, but ingots can be produced with about 3% of the energy demand of newly made material by collecting, melting down and refining used aluminum.

Chips and cuttings are not the only materials to be recycled into viable raw materials. Trial products that are produced in test-runs that serve to verify that automatic machine programs do not contain flaws are collected and used as raw materials for new industrial products.

The fact that Cosina is recycling aluminum and other metal chips and cuttings into industrial materials testifies to our corporate stance of effectively utilizing energy and the planet’s limited resources. Using recyclable materials is as important as making high-end products our customers can use for a long time.