Cleaning optical elements according to their inherent material properties

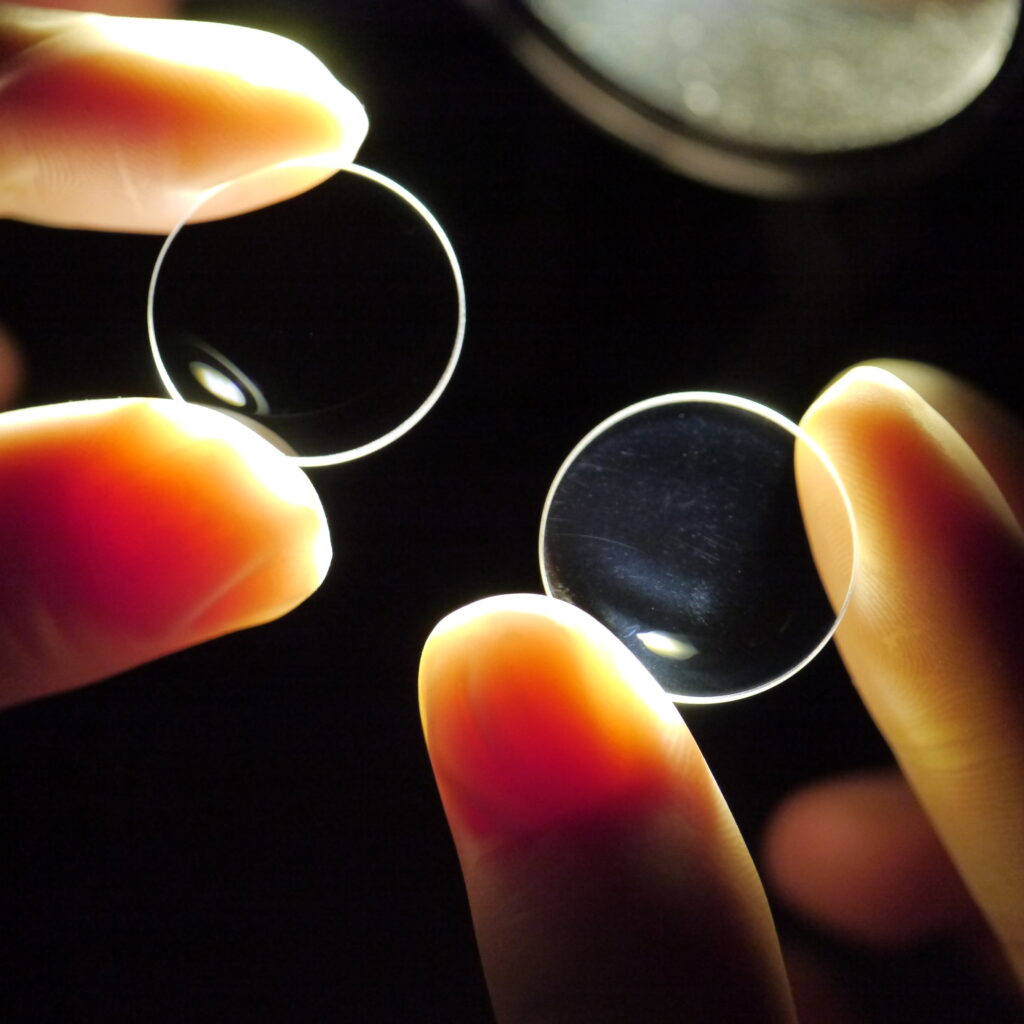

Traces of abrasive, glass dust and other minute particles adhere to and embed in the surfaces of polished optical elements. Because these tiny particles can diminish optical performance, they must be removed by prudent cleaning before the optical elements can be sent to the next process for coating, etc. Optical elements are cleaned by soaking them in cleaning baths and subjecting the baths to ultrasonic vibrations. The above photograph shows two lenses after a cleaning test. The one on the right was damaged by soaking in cleaning agent and cleaning with ultrasonic vibrations. The cleaning agent in this case was deionized water. Optical glass comes in diverse types of varying resistances to water, acids, alkalis, cleaning agent formulas, etc. Glass material that is particularly weak against water erodes on the surface when soaked in water and agitated by ultrasonic vibrations. The minute latent scratches that occur in polishing processes grow and become conspicuous on the surface after cleaning.

So, cleaning processes suited to the material properties are used. All types of glass material that can withstand cleaning agents, emulsifiers, water and alcohol are subjected to ultrasonic vibrations while soaking in a series of automatic baths, but delicate types of glass material with low resistance are soaked by hand and in some case in specially prepared baths of compatible formulas. All types of optical elements ultimately acquire chemical resistance when coated, but we work with many types that require special handling in the lead-up steps to that.

Types of optical elements that are particularly weak against water are wiped clean one by one by hand, instead of soaking them in a cleaning bath. The optical element on the right in the opening photograph was wiped clean by hand to avoid attacking by water and ultrasonic vibrations. From a productivity perspective, optical element with material that is weak against water is like a problem child. If we used just optical element that could be cleaned in an automatic bath, we could save ourselves a lot of time and trouble. So, why do we use delicate types of glass materials that have to be manually wiped clean? Because, to configure optical elements designed to deliver the best optical performance, glass of the most suited refractive index and dispersion value is chosen for each individual element. Our choice to prioritize optical performance regardless of how troublesome it may be, makes us at Cosina even prouder of the high-end optical devices we make.