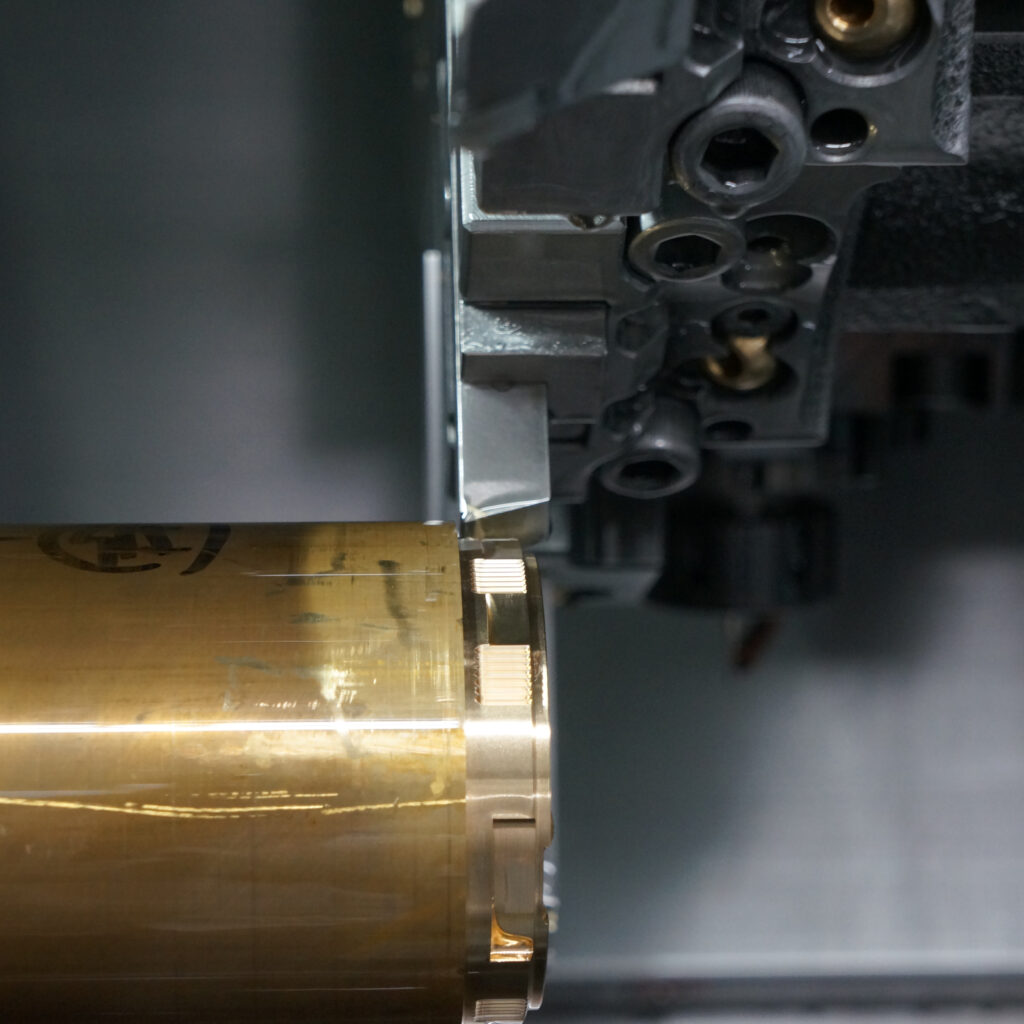

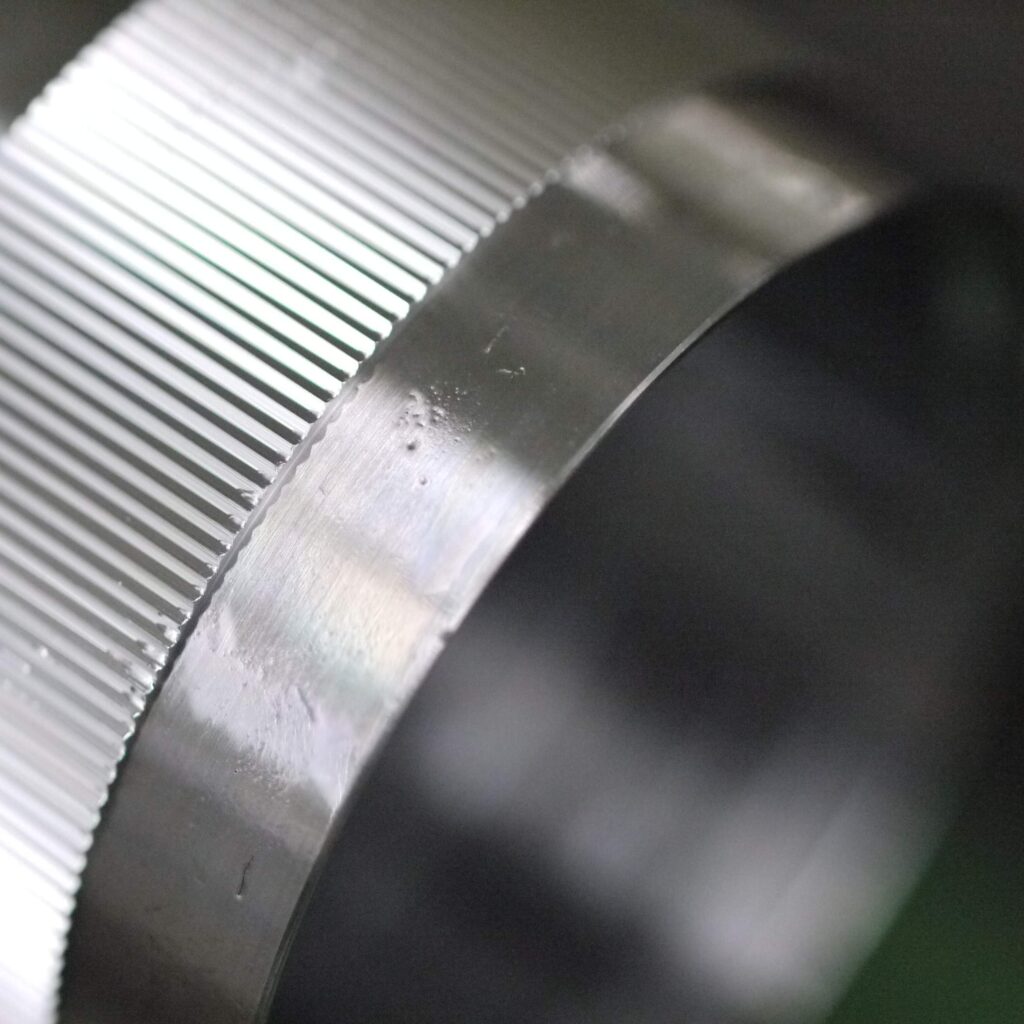

Knurling applied to rings

Have you heard the term “knurling”? Knurling is a type of metal processing that cuts grooves into a cylinder to enhance gripping when handling or operating the cylinder. The grooves are machined one by one in the cylinders that serve as the focus ring and diaphragm ring. They look like a roulette wheel. This is called a straight knurl pattern. It effectively prevents slipping in the direction of rotation and is esthetically attractive. Without precision milling technology, the external appearance can be destroyed as the tool can scar the ends of the groove or finish the last groove at an uneven interval.

It was standard practice to knurl interchangeable lenses until the 1960s, but after that it became popular to mill a single, wide yet shallow groove in the metal base and fit it with a synthetic rubber ring. Today, many of the barrel parts of interchangeable lenses are made of engineered plastics. In the pursuit of high cycle productivity, a resin ring is mounted on an injection-molded shell or the ring and handling grooves are molded as a single piece.

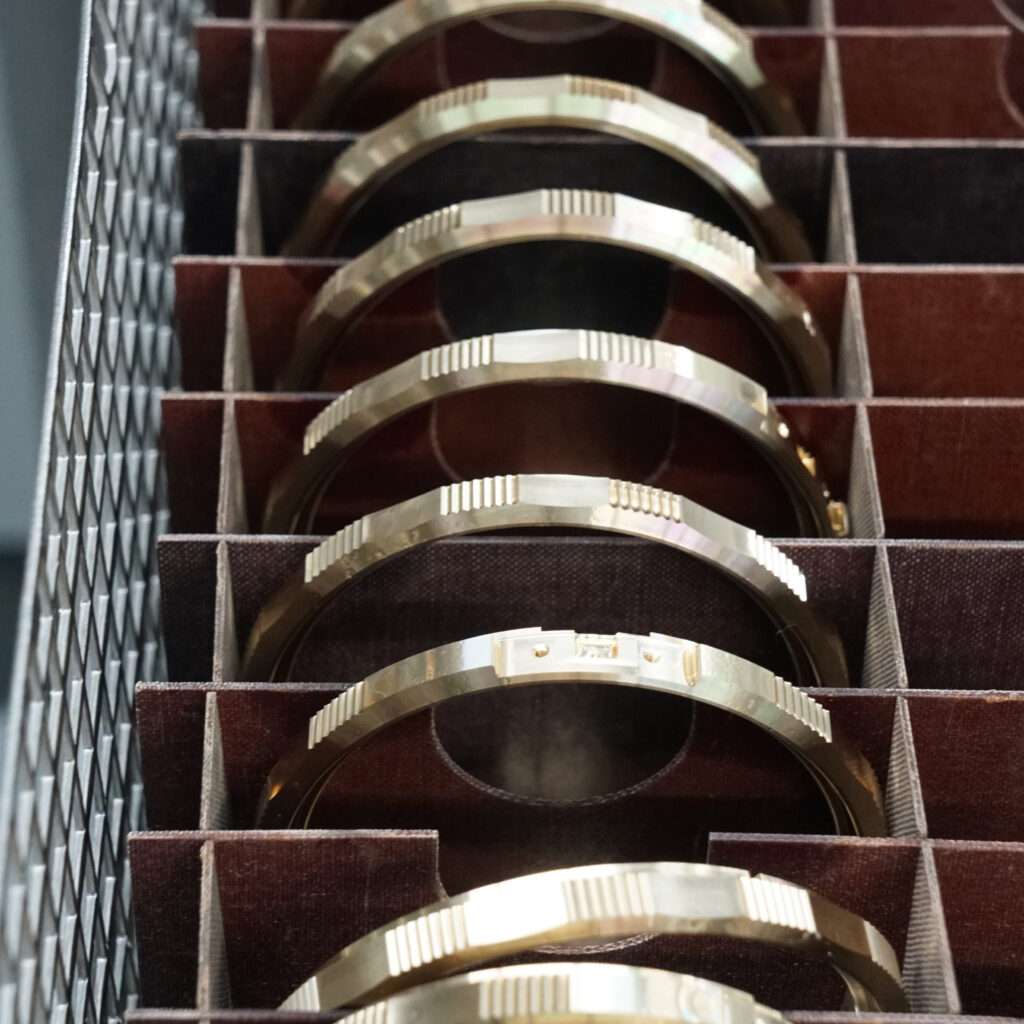

Meanwhile Cosina continues to use the traditional standard knurling technique.

The knurled interchangeable lenses require several processes, manpower and time to machine, but we believe that the feel, durability and beautiful finish reflect the labor and passion that go into making them. The knurling refines a high-end interchangeable lens to an effective handheld tool.