Special coatings applied to prisms

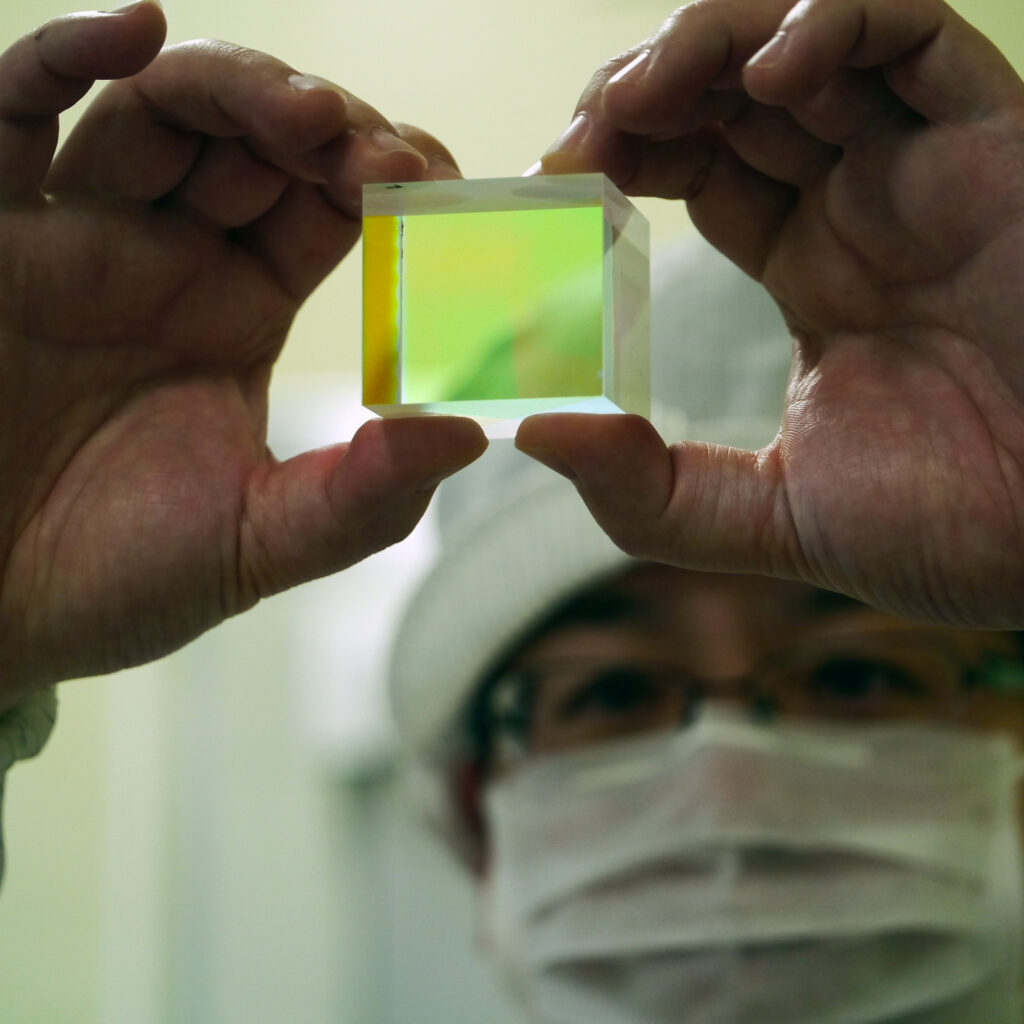

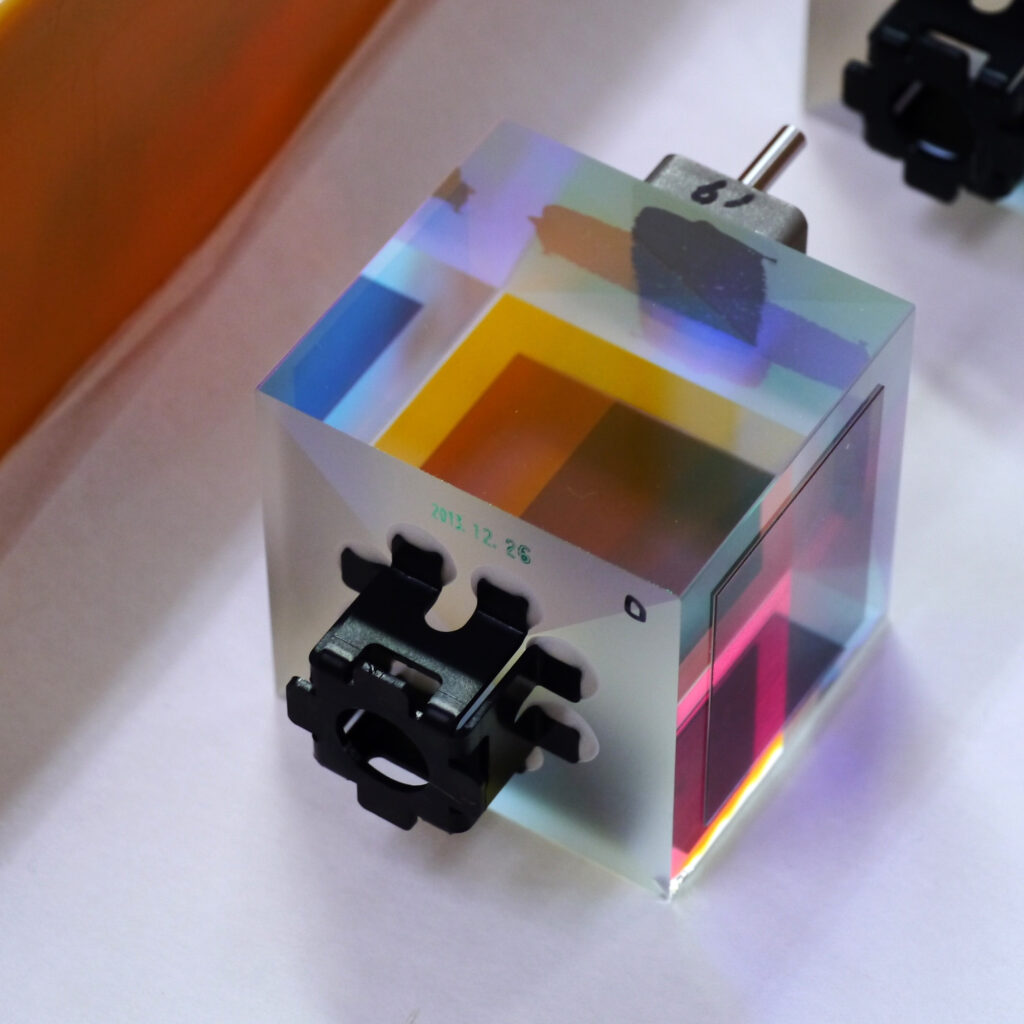

Though made of transparent optical glass, this mysterious object projects various colors like pale-green and yellow when exposed to light. The above photograph shows an operator holding a prism that is made at Nanase factory for special applications. It has a shape close to a cube and looks like a block of glass. In fact, it is made of right-angle prisms precisely attached to each other. And, a special coating is applied to the contacting planes of the prisms. The purpose of this optical device is to reflect only light of certain wavelengths and transmit light of other wavelengths. It divides a seemingly white light source into different colors and mixes them again. So, many such devices are used in the piece of equipment called a “color separation and synthesis system”.

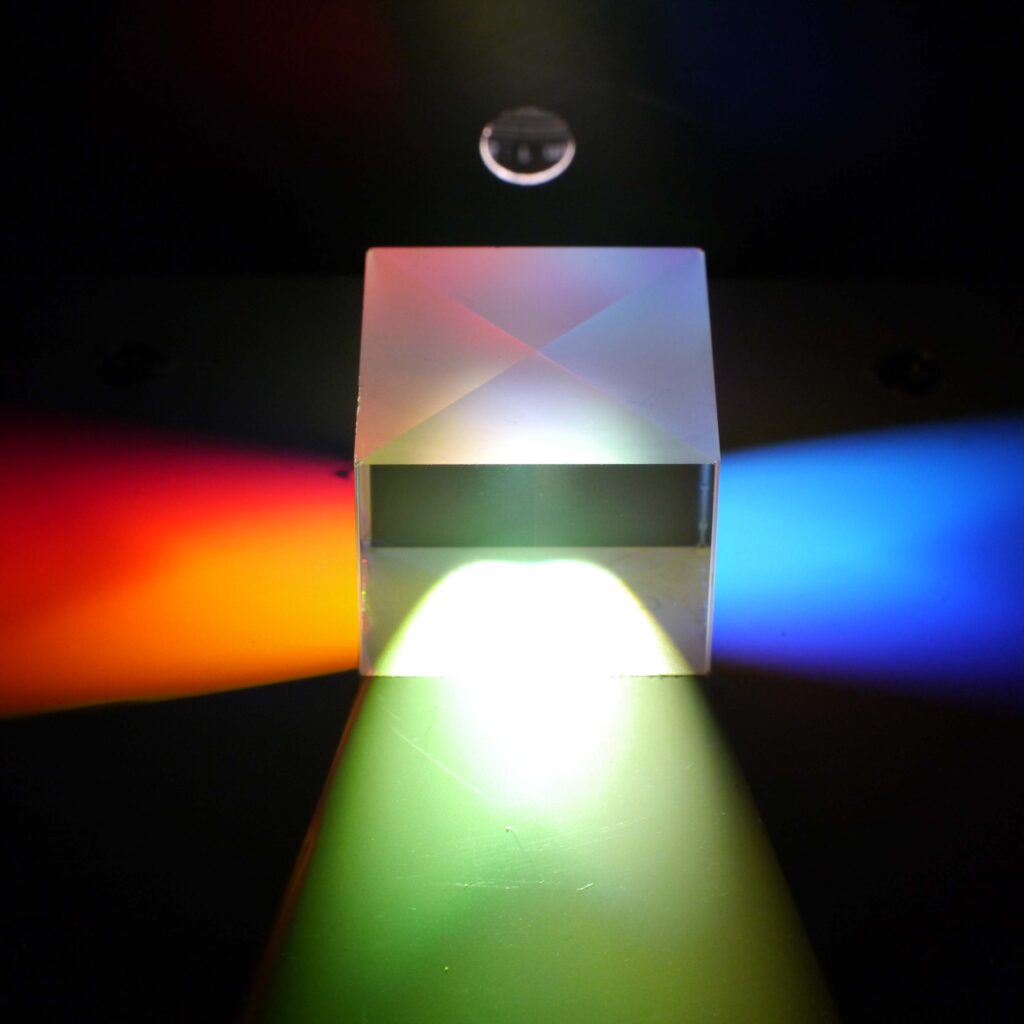

Generally, photographic lenses transmit incoming light by eliminating as much unnecessary reflection off the surfaces of several composing elements as possible. In a color separation and synthesis system, it becomes important if the device can reflect light in a specific wavelength range. Two kinds of optical devices that have such characteristics are dichroic mirrors and prisms.

To provide a coating that prevents reflection and homogeneously transmits light, it is necessary to overcome numerous difficulties. So, dichroic optical devices are made with very complicated processes and stringent controls. Though it depends on the application, dichroic optical devices have more coated film layers than lenses with antireflection coatings, with as many as 50 layers being applied at times.

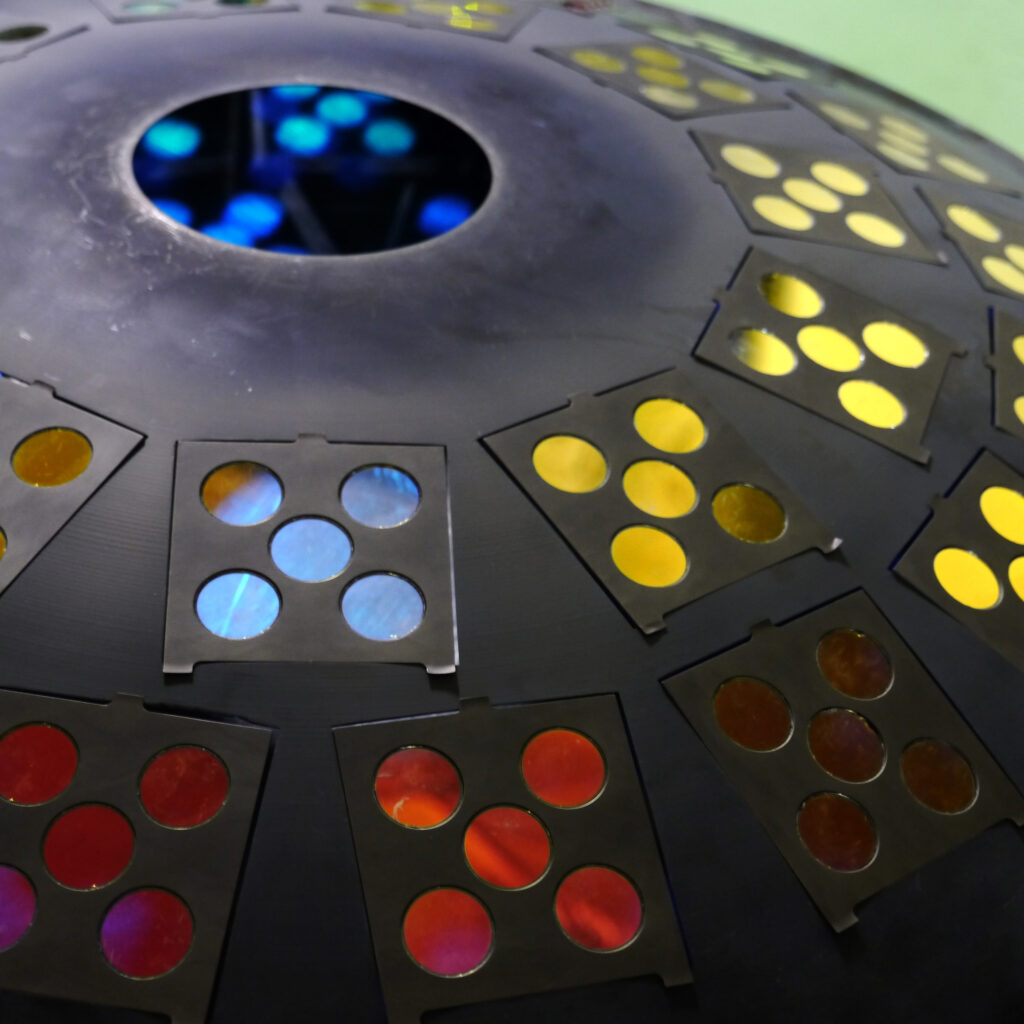

Projectors are typical products based on such a color separation and synthesis system. Prisms and mirrors made with special coatings are at the center of the devices that separate light into RGB colors, synthesize them again and then project them onto a large screen. In particular, with projectors delivered to movie theaters, even the slightest color deviation is not allowed because it directly affects the quality of content to be shown. It is impossible to make such delicate, complicated optical devices without selecting the proper evaporant, designing the right film thickness and layering sequence, and having the technology and know-how for controlling film thickness on the nano-order. And, we apply the manufacturing technology that has been developed in the making and applying high-grade antireflection coatings for photography.