Why engraving over printing

You may have recently seen interchangeable lenses without numerical figures inscribed on the focus ring. This specification is adopted with products whose users do not care to know the distance to the subject they are focusing on. On the other hand, products for professionals and high-end amateurs have figures on the focus ring. And, if you look closely at those figures you should be able to see that in many cases the figures are printed. But, the ink that is used does not stand up to years of use and can fade, and repairing that is tantamount to replacing the entire unit. That kind of manufacturing runs counter to the principles at Cosina.

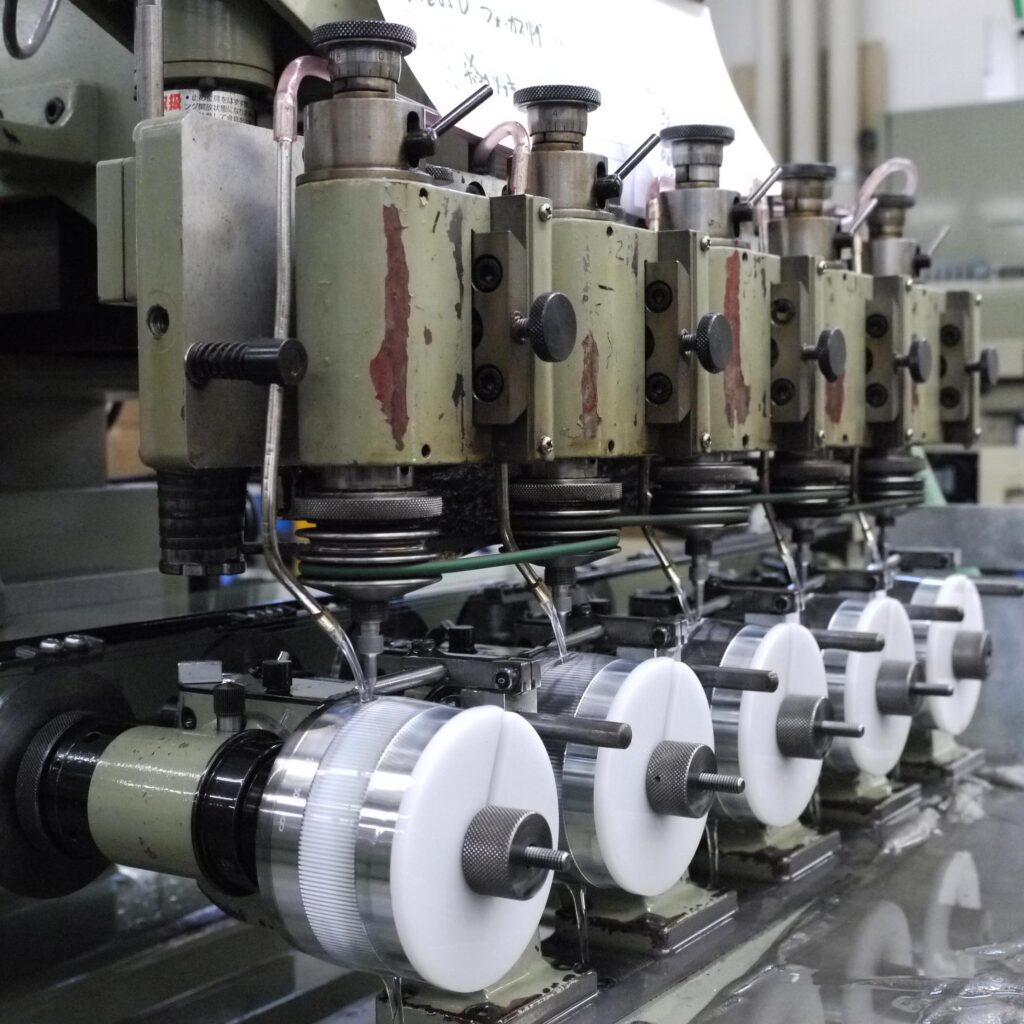

The automatic engraving machine carves infinity mark and distance indications in the focus rings of high-end interchangeable lenses. By machining the metal, numerical figures, letterings and symbols are processed to the same depth.

Compared to printing, engraving characters one at a time takes more time and cost. Though old, but the well-kept engraving machines are running full time to engrave numerical figures, letterings, symbols and brand names. The grooves that have been caved are then flooded with paint to ensure an entirely higher level of durability than seen with printing. That is why we continue to use engraving machines rather than go with silkscreen printing.

Though quick and inexpensive, silkscreen printing runs the risk of rubbing off when touched by hands. In contrast, engraving is meticulous and time-consuming work, but it renders a strong finish that is not superficial and will not fade. After the characters have been engraved one by one, the parts are sandblasted, plated or treated in other ways, then forwarded to a finishing process where characters are filled by paint. We are confident that the customers who like Cosina products understand which specification should be adopted for high-end optical products that are meant to be used often and for a long time.